6 Commercial Coffee Equipment Maintenance Tips

Making sure all the necessary equipment is running smoothly will always be a top priority as it is the lifeline of your café and core of your restaurant. A well-maintained and cared-for machine will deliver more consistent results leading to happier customers.

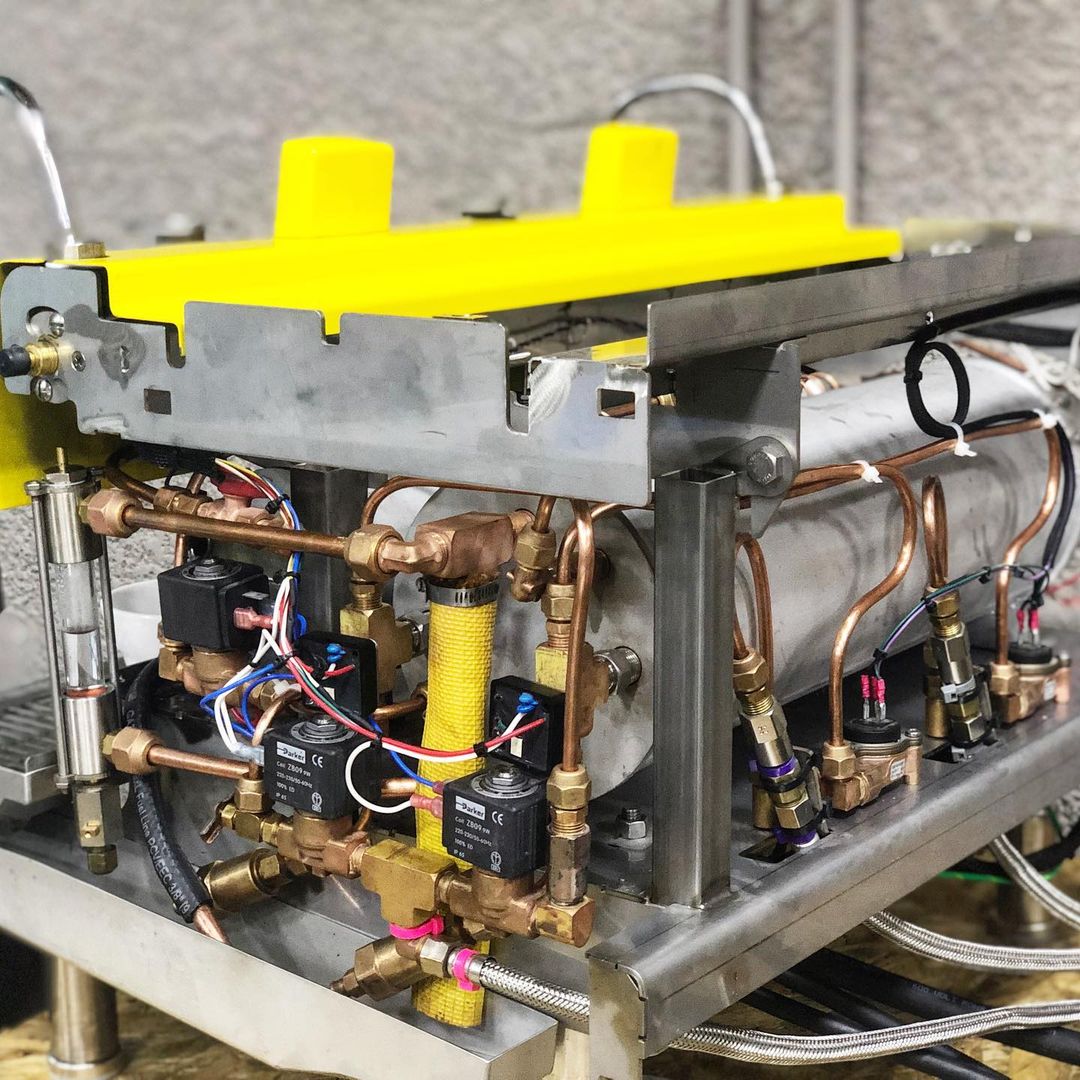

Specialty Coffee machines like Synesso’s MVP Hydra and S200 are built to last for a lifetime with its composition to allow its users the best performance possible. Having said this, Improper maintenance and handling of any machine will not only alter the taste of your coffee but also cost you a lot in the long term. Moreover, serious health hazards arise from poorly maintained equipment affecting the entire chain from employees to customers.

Therefore, you should always make sure that your equipment is installed correctly and perform a mandatory daily maintenance for your Synesso espresso machine.

We have listed all the tips on how to maintain your Synesso espresso machine and espresso equipment like a professional. The first thing we will have to do is divide your mandatory machine cleaning and maintenance tasks into daily, weekly, quarterly, and annual timelines.

Daily Maintenance To do’s

One easy to do thing that will keep your machine making great espresso day to day is to ensure that your portafilter and the screen in the brew group is free of coffee grounds. This means giving your portafilter a quick wipedown after every shot, ensuring it is dry and clean.

- A must do at the end of service is to take a teaspoon of machine detergent (espresso machine) and put it into the blank filter and insert it into the espresso machine group head. Enable rinse and keep it running for about ten seconds and turn it off for about ten seconds. This process must be repeated about four times.

- You can let the blind filter stay in the group head for at least five minutes. This will let the chemical remove hard stubborn oils and coffee residue which is present.

- You will need to perform a backflush of your coffee brewer once every day without miss. The loose coffee from the group and shower heads, seals should be scrubbed out all with a group head cleaning brush. Use a delicate hand while performing this step.

- The milk wand with regular use, collects immense amount of residue! Perform a cleaning of the milk wand effectively use a recommended milk cleaner. Get in touch with your espresso machine supplier or service inspector for recommendations.

- Dump and rinse all drip trays. Use warm soapy water and let it dry overnight.

Once the maintenance procedures are complete – Use a clean, damp cloth and a non-abrasive cleaner to wipe down everything so that there is no water, coffee or milk residue on the equipment’s.

A step which is often overlooked or missed is to clean brew pots and brewing chambers. All pots and filter baskets should be washed and sanitised by hand or in a dishwasher.

Use a bottle brush or a sponge to clean thermal servers and air-pots. Never immerse air-pots or thermal containers in water, this may cause physical danger and will cause damages to the equipment and property.

Weekly Maintenance Activity and To Do

Let me tell you this before we start. The weekly maintenance is a bit more elaborate and is advisable to do this in a group of two or more. The head barista oversees, co ordinating this activity and ensuring that his team members learn the process in detail.

- Let us start clean. Scrub the internal chamber of your Synesso coffee machine with a soapy sponge and wipe with a damp cloth.

- Prepare a guide and remove all removable parts of the espresso machine such as filter baskets, group handles, group head shower screens. Using a solution of ¼ hot water and 1 tbsp of espresso machine detergent soak them overnight.

- Wash away the coffee dregs (the remnants of liquid left in a container, together with any sediment), all drip tray components, and the water reservoir thoroughly with espresso machine detergent and water.

- To clean the waste pipe, take 1 tbsp of bicarbonate soda and place it in the brass collecting tray underneath the drip tray. This will help keep the waste pipe clean and avoid leakages caused by clogging.

- We all know the importance of water pressure! We should check the pressure gauge on the installed water filter system every week. This is also especially important and will help us in replacing any filters that are out of date.

- An important thing to check for is mineral deposition and calcification in the spray-head. If present, remove it (if removable) and clean by hand or place it in a dishwasher. Calcification affects the taste of your coffee and is difficult to calcium deposits.

- Some manufacturers provide cleaning tools with their equipment during purchase. This can help the spray organise the head as well as the hole where the spray head sits.

Quarterly Maintenance Activity and To Do

Coffee machines need some minor service every three months. This service is elaborate and complex. Only a certified service technician approved by the distributor conducts this activity. The head barista oversees, co ordinating this activity and ensuring that his team members learn the process in detail.

The main goal of this service will be preventative, and the services is usually conducted after closing hours by an authorized technician:

- Testing the group flow rates and temperature. The baristas take care of the groupheads are clean it regularly to avoid mineral deposition. The group flow and temperature checks during the activity notes out any irregularities occurring in the functioning of the group heads.

- Testing all switches. All operating switches need to be examined for correct conductivity and wear & tear as these are main points of contact during operations.

- Testing the water quality of the boiler and the grouphead. By now, we have established the fact that a solid RO and filtration system is essential for consistency in the finished beverage. As “mineral deposition” and “calcification” is a major factor the water quality from the RO system and exiting the group heads are tested for TDS and PH readings. Necessary suggestive and corrective actions are performed by the authorised technician.

- If the water you use has low mineral-content, check every month, and perform descaling every three months.

- Clean the insides of the brewer using a commercial cleaning product. You can also use other substances for descaling such as one ounce of citric acid in water for one brew cycle or a mixture of vinegar and water in a 1:1 ratio.

Twice Yearly Maintenance Activity and To Do

The Bi-yearly service is handled by the espresso machine supplier on a pre-assigned contract. It is important to maintain a strict timeline and perform a major service at least two times a year.

This includes the above-explained services (daily, weekly, monthly) and the additional service given below:

- Replacing espresso machine gaskets. The gaskets are usually worn out because of heavy usage during operations.

- The replacement may include the Espresso machine Group head, O-rings, Steam arm and Steam Valve gaskets.

The Steam valve gaskets require cleaning or changing as during operating the machine, constant heating and cooling makes them harder and lets them wear much faster. A tell-tale sign is being able to over tighten the gasket. And another one is leaks from anywhere.

Renovating steam assembly. Refers to the de construction and re-assembly of the steam wand. Steam valve holders are more commonly damaged. Repairs are done to the damaged parts in the assembly.

Reconditioning the water tap. Refers to the de construction and re-assembly of the water tap present in the espresso machine. The boiler connections and adjustments are corrected where necessary and boiling temperature checks are done.

Changing the anti-suction valve. Anti-suction valve prevents the water from re-entering the boiler chamber from the group head post extraction. On inspection and damages if any, the anti-suction valve is changed.

Cleansing the boiler level probe. The level probe of the boiler is cleaned

Annually Maintenance Activities At Specialty Batch Coffee we provide all our partners who use Synesso for their operations a 1 year annual service and maintenance included in the contract.

If you have been maintaining the espresso machine all the while, at this point, there will not be much remaining to do. It is always better to get an authorised technician from the supplier go through your machine because the technicians there are going to be very thorough in cleaning and repairing your machinery.

The authorised technician can open your machine and wipe away coffee oils and residue build up on the inner parts. They also conduct a descale activity on your espresso machine and replace any parts that need to be adjusted or fixed. Finally, they will submit a service report that will let you know of any faulty areas of your machine.

The following can be done once a year and is always present in the annual maintenance activity:

Replacing of the espresso machine gaskets. The gaskets that have worn out because of heavy usage needs to be changed as it effects the delivery and extraction. This will include the group head, O-rings, steam arm, and valve (steam) gaskets.

Changing the pressure safety-valve. A pressure safety valve is a safety device designed to protect a pressurized vessel or system during an overpressure event. Changing this when required or yearly is preventative measure and contributes to a safe work environment.

Portafilter baskets change. The porta filter baskets are made of hardened stainless steel and are built to last. With a year’s use and activity, it is always a good idea to change the portafilter basket.

Checking waste pipe and replacing if needed. Changing the waste pipe is a minor event, but care will be taken to see that no growth or blockage is occurring.

Changing the capacitor on the pump motor. A capacitor is a device that stores electrical energy in an electric field. It is a passive electronic component with two terminals. Changing this when required or yearly is preventative measure and contributes to a safe work environment.

Looking for leaks. A Synesso espresso machine is built to last. And complications due to leaks are rare. Most common leaks like form the steam wand connection can easily fixed with a wrench.

During the annual maintenance process, we de construct the Synesso machine and re assemble it. This will give You, our valuable partner and our authorised technical a clear picture of the machine and issues, if any.